Glass Bottle Factory

United Packaging Company Glass Bottle Factory currently operates 32 workshops. Among these, 20 workshops are dedicated to glass bottle production, equipped with 25 furnaces and over 180 production lines. The base has a daily production capacity of 1,500 tons of glass. Advanced technologies, including full furnace thermal insulation, automated inspection, and packaging processes, have been implemented.

Additionally, the base houses 6 workshops for rubber stoppers, aluminum-plastic caps, ampoules, prefillable syringes, and 8 workshops for power generation, coal gas production, mechanical and electrical equipment, raw material compounding, and corrugated carton manufacturing.

Production Capabilities

As of 2016, the base achieved a soda-lime molded injection vial production output of 7 billion pieces, capturing a 75% market share in China. The amber glass bottle workshop, utilizing advanced thermal insulation technology, reduced energy consumption by over 28% and produced 2.5 billion pieces, primarily for export. This base is recognized as the largest amber glass bottle manufacturing facility in Asia.

Other significant production capabilities include:

-

4.4 billion butyl rubber stoppers (largest production line in China)

-

1.1 billion low-borosilicate tube glass vials

-

1.3 billion low-borosilicate ampoules

-

2 billion soda-lime cosmetic glass bottles

-

0.5 billion soda-lime infusion bottles

-

0.2 billion soda-lime food glass bottles

-

18,000 tons of low-borosilicate glass tubing

-

0.2 billion neutral borosilicate molded glass vials

-

0.2 billion blue and green glass bottles

-

20 million neutral borosilicate tube glass vials

-

65 million neutral borosilicate ampoules

-

70 million plastic bottles

-

0.5 billion aluminum-plastic caps

-

15 million prefillable syringes

-

70 million dental glass cartridges

Technological Advantage

The base boasts a post-doctoral scientific research workstation and has pioneered the application of 5-gob technology for molded vial production. It has introduced advanced automated production and inspection lines from overseas, earning recognition from the French Technical Quality Supervision and Evaluation Commission as a provider of high-quality products and technologies for the European Union market.

The base holds 170 scientific and technological achievements, 142 patented technologies, and has independently developed high-flint glass materials and lightweight, thin-walled molded pharmaceutical glass vials, which have received national new product certification. Additionally, the base has filled a domestic gap in neutral borosilicate glass products.

Quality and Environmental Commitment

The United Packaging Factory Glass Production Base upholds the company's spirit of "Realistic Innovation, Hard Endeavor." In 1998, the factory obtained quality management system certification and product certification from the China Quality Mark Certification Group. It has subsequently established an environmental management system certified to ISO 14001 standards. In 2006, the factory adopted the OSAS 18001 occupational safety and health standards, becoming the first in its industry in China to achieve ISO 19001, ISO 14001, and GB/T28001 certifications. The factory further strengthened its quality management system in 2015 by obtaining ISO 22000 food safety system certification from SGS, meeting the stringent requirements of domestic and international markets.

In December 2009, the glass factory's quality inspection center received laboratory accreditation from the China National Accreditation Service for Conformity Assessment (CNAS), complying with ISO/IEC 17025:2005 standards. This enables the factory to effectively monitor product quality from raw materials to finished goods and provide third-party inspection services within its scope of authority.

Plastic Bottle Factory

United Packaging Company Plastic Bottle Factory is a modern manufacturing plant specializing in a wide range of plastic bottles and containers. We employ advanced molding techniques including rotational molding, extrusion blow molding, injection blow molding, reheat and blow molding, and injection stretch blow molding. With extensive production experience and sophisticated technology, we can provide customized solutions for plastic bottles and containers of various specifications, materials, and shapes. Equipped with world-class production equipment and testing instruments, our factory has passed ISO9001 quality management system certification, ensuring the stability and reliability of product quality.

Production Capabilities

-

Rotational Molding: Produces large, hollow, seamless plastic products such as water tanks, storage tanks, and toys.

-

Extrusion Blow Molding: Primarily produces hollow containers like detergent bottles, oil bottles, and plastic drums, offering high production efficiency and low costs.

-

Injection Blow Molding: Suitable for producing plastic bottles with integrated bottle mouth and body, such as beverage bottles and cosmetic bottles, providing aesthetic appearance and good sealing performance.

-

Reheat and Blow Molding: Mainly used for producing PET bottles, featuring fast production speed and low energy consumption.

- Injection Stretch Blow Molding: Suitable for producing PET bottles with high transparency, high strength, and thin walls, such as carbonated beverage bottles and mineral water bottles.

Creative Engineering & Technological Advantage

-

Multi-cavity molds: We have a variety of molds to meet the customized needs of different customers, shortening product development cycles.

-

Automated production lines: The factory is equipped with fully automated production lines, realizing automation of the production process from raw material mixing to finished product packaging, improving production efficiency and product quality.

-

Advanced testing equipment: We have advanced testing equipment such as three-coordinate measuring machines and tensile testers to conduct comprehensive testing of products, ensuring that product quality meets standards.

-

Technology research and development: We have a professional R&D team that continuously innovates in technology, developing new products and new processes to meet market demand.

Quality and Environmental Commitment

-

Strict quality control: We have established a complete quality management system. Each link from raw material procurement to finished product delivery is strictly controlled according to standards to ensure the stability and reliability of product quality.

-

Environmental materials: We select environmentally friendly materials such as recycled plastics and biodegradable plastics to reduce the impact on the environment.

-

Energy conservation and emission reduction: We achieve energy conservation and emission reduction through optimizing production processes, using energy-saving equipment, and so on, reducing production costs.

United Packaging Company Plastic Bottle Factory is a professional manufacturer of plastic bottles and containers integrating research, development, production, and sales. With advanced equipment, sophisticated technology, and a commitment to quality, we are dedicated to providing high-quality plastic packaging solutions for global customers.

Metal Bottle Factory

United Packaging Company Metal Bottle Factory is a large manufacturing plant specializing in high-quality metal bottles, including aluminum bottles, tin cans, stainless steel bottles, and titanium bottles production. Equipped with advanced production euipment, sophisticated craftsmanship, and a rigorous quality management system, we provide customized and diversified metal bottle solutions for global customers. Strategically located in China, our factory enjoys convenient transportation, facilitating raw material procurement and product distribution.

Production Capabilities

Our state-of-the-art production lines enable us to manufacture a wide range of metal bottles in various sizes, shapes, and specifications to meet diverse customer needs. From traditional round bottles to trendy irregular shapes, and from small-capacity travel bottles to large-capacity sports water bottles, we can offer customized solutions.

-

Aluminum bottle and aluminium cans production lines: With a monthly capacity of 500,000 units, this line specializes in producing sleek and lightweight aluminum bottles, ideal for beverages and personal care products.

-

Stainless steel bottle production lines: Capable of producing 300,000 units per month, this line focuses on durable and high-end stainless steel bottles, often used for outdoor activities and premium products.

-

Tin cans and tin container production lines: Capable of producing 2,200,000 units per month, these lines produces corrosion resistant, recyclable, environmental protection and 100% food safe containers for a variety of foods and content.

-

Titanium bottle production lines: With a monthly capacity of 100,000 units, this line produces lightweight and corrosion-resistant titanium bottles, catering to the high-end market.

Sophisticated Technology & Advantage

-

Surface treatment technologies: We have mastered various surface treatment techniques, including anodization, electroplating, and spraying, to provide metal bottles with a rich variety of colors and textures, meeting customers' personalized demands for product appearance.

-

Customized design capabilities: Our professional R&D team can design and develop products based on customer requirements. From product shape to functional design, we offer comprehensive customization services.

-

Intelligent production: The factory has introduced an intelligent production management system, realizing automation and digitalization of the production process, improving production efficiency and product quality.

Quality and Environmental Commitment

-

Strict quality control: We have established a complete quality management system. Each link from raw material procurement to product delivery undergoes rigorous inspection and testing to ensure product quality meets international standards.

- Environmentally friendly materials and processes: We select environmentally friendly materials and adopt environmentally friendly processes to minimize the impact on the environment. Our products comply with relevant environmental standards and have passed the corresponding certifications.

-

Continuous improvement: We continuously improve production processes and management systems to enhance product quality and production efficiency, while reducing production costs and providing customers with more competitive products.

United Packaging Company Metal Bottle Factory is a professional metal bottle manufacturer integrating research, development, production, and sales. With advanced equipment, sophisticated technology, and a commitment to quality, we are dedicated to providing high-quality aluminium bottles, tin cans, stainless bottles and titanium bottles with BPA-free products to global customers.

Factory equipments and office scense

Finished plastic caps warehouse

Finished plastic caps warehouse

Plastic raw material warehouse

Plastic raw material warehouse

Finished plastic bottle warehouse

Finished plastic bottle warehouse

Medicine bottle inspection room

Medicine bottle inspection room

Plastic caps workshop

Plastic caps workshop

Plastic bottle workshop

Plastic bottle workshop

Workshop of plastic bottle

Workshop of plastic bottle

Plastic bottle workshop

Plastic bottle workshop

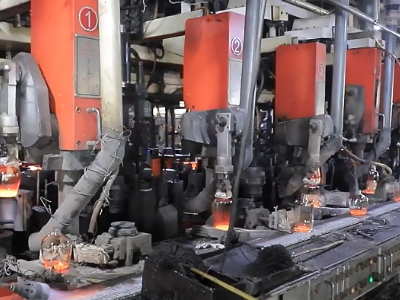

Glass production machine

Glass production machine